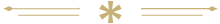

The manufacturing of chocolate is a complex process and requires using a large number of machines and devices. If we are to delight in even the smallest product that contains chocolate, the basic ingredient, i.e. cocoa beans must undergo a long multi-stage process of conversion into cocoa mass. Depending on the type and country of origin cocoa beans differ in terms of their level of purity. Meticulous and complete cleaning is the necessary condition to obtain tasty, healthy products and is the first stage of cocoa beans processing in our factory. The cleaned beans are debacterised in order to reduce the bacteria load to a safe level and obtain a raw material characterised by high microbiological purity.

Raw cocoa beans contain on average 6-7% of water and are characterized by an unpleasant astringency and bitterness. For this reason they undergo roasting in high temperatures. Cocoa beans are mostly made up of a kernel, husk and a germ. Inside it contains a precious ingredient – cocoa fat (cocoa butter) that we want to extract. Only the roasted kernel that undergoes deshelling (breaking) is of value for cocoa mass production. The deshelled nib is crushed in a two-stage process, in which after breaking the cell walls and releasing the substances contained therein, it is transformed into a liquid and finely crushed cocoa mass.